We are putting a lot of pressure on tinned tuna

Can tinned tuna become even better if exposed to high pressure? We are about to find out.

We will explain why high pressure is smart to use in a little while. Firstly, however, we need to talk a bit about bacteria in food, and how to get rid of them.

Food products that have a long shelf life often require high heat treatment to kill the bacteria that are naturally found in the food. The downside is that this can affect the quality, colour, consistency and nutritional value of the food. However, if a combination of high pressure and heat is used, one can lower the temperature and still kill the same number of bacteria. This produces food of better quality.

The combinations of pressure and heat that are chosen depend on the type of food product and the desired shelf life. In order for each individual product to be sufficiently safe, the processes must be carefully tested and documented.

Trials have been conducted on tinned tuna and tinned mackerel in tomato sauce to find the best combination of pressure and heat for these products.

Intensive treatment for food with long shelf life

We have always heard that bacteria are killed when food is boiled. If one boils food long enough, the vast majority of bacteria are killed. However, some bacteria may survive even when we boil food for long periods of time. The bacterial spores can be a challenge during all types of heat treatment. This is due to the fact that spores withstand high temperatures.

Only a few types of bacteria can produce spores, but they can be found in a variety of raw foodstuffs and ingredients that we use when cooking. Bacteria from the genus Bacillus and Clostridium are able to produce spores, and some of these can survive heat treatment and cause foodborne illness.

Therefore, an aim of heat treatment is to use a combination of high temperature and time that will kill even the spores.

An alternative way to kill bacteria is to expose them to several different stress factors at the same time, such as both heat and high pressure. Combinations of different techniques are very successful and are widely used in food production today.

How to give food a longer shelf life?

Food that has a long shelf life can be divided into two main categories:

(1) Sterilised food (also called tinned products) that can have a shelf life of several years. Tinned mackerel and tinned tuna are examples.

(2) Pasteurised food, that often has a shelf life of three to five weeks when stored in the refrigerator.

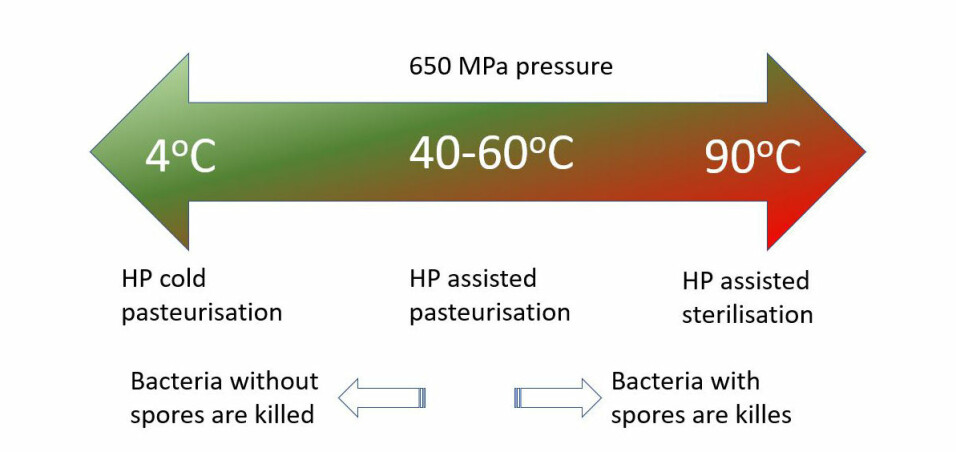

If you want to kill all the bacterial spores in sterilised food, one must reach sterilisation conditions that are equivalent to 121oC for three minutes. Tinned food is processed under these conditions and can be stored at ambient temperatures.

In relation to pasteurised food, a minimum of 90oC for ten minutes is often used, but the food must then be refrigerated. Pasteurisation allows some bacteria to survive, but food safety will still be assured for a limited shelf life by subsequently refrigerating the products.

In recent years, several new technologies have emerged that can be combined with traditional sterilisation and pasteurisation for food preservation. High pressure treatment alone, or in combination with heat, is one of these treatments. We are able to conduct trials that involve pressures of up to 650 MPa. This is equivalent to the pressure that would be under a 65 thousand metres high water column. As a rough comparison, 400 MPa is equivalent to 26 cars placed on a postage stamp.

By finding the right combination of pressure and temperature, it is possible to achieve both sterile and pasteurised foods at lower temperatures compared to heat treatment alone. This is called Pressure Assisted Thermal Sterilisation, PATS (when sterilising) and Pressure Assisted Thermal Pasteurisation, PATP (when pasteurising).

Advantages of combining technologies

Today, people want fresh and nutritious food that has been processed as little as possible. Therefore, it is a goal to develop new ways of processing food in order to achieve higher food quality and desired shelf life.

There are well established international sterilisation and pasteurisation requirements and recommendations regarding heat treatment levels. Therefore, when using new food processing technologies it is important to document that the new production method(s) kill bacteria and bacterial spores sufficiently, and provide corresponding levels of food safety.

There are a number of factors that play a role regarding how effectively bacteria and bacterial spores are killed in certain type of food. How acidic the product is (low pH), the fat content, the use of preservatives and any processing and packaging of the product are some examples.

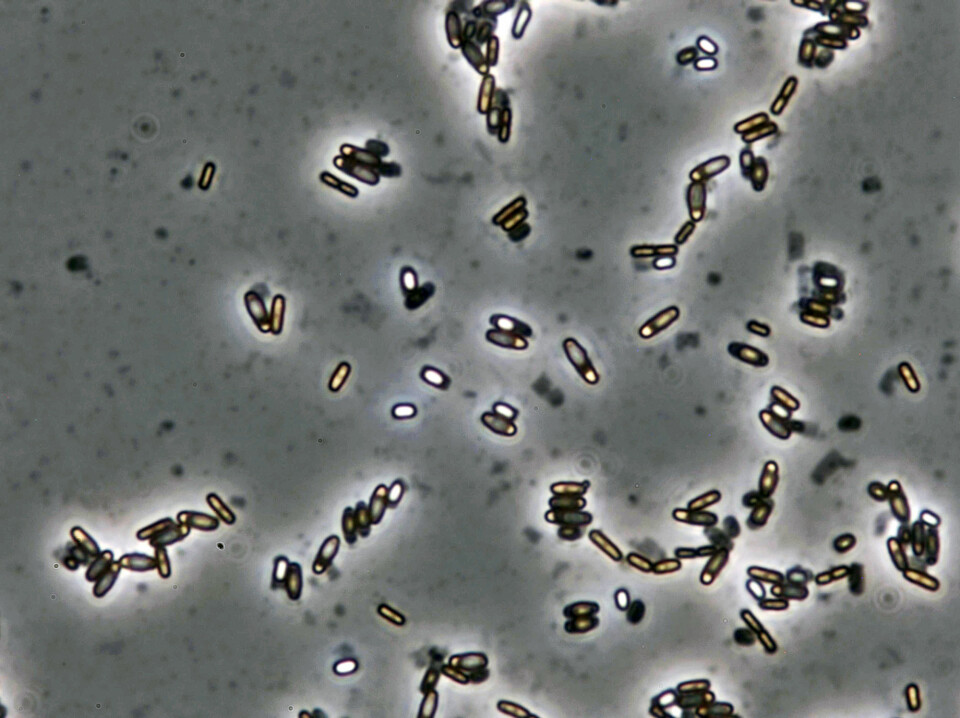

A hundred years ago (1920), the researchers Bigelow and Esty published some of the first mathematical models of how bacterial spores are killed through a heat treatment process. This was done by adding various numbers of bacterial spores to tinned foods. The tins were then heated, and the number of surviving bacterial spores were counted.

It is important to document the amount of bacteria killed in the food under the relevant conditions. So-called bacterial load trials are still conducted on foodstuffs to document whether spores have been sufficiently killed.

Full pressure on mackerel in tomato sauce

Over the past year, we have investigated how spores from Bacillus subtilis, B. pumilis and B. licheniformis added to mackerel in tomato sauce and tuna can be killed in tinned products. We have studied different degrees of preservation by adjusting the amount of salt and acidity levels (pH), and storing food at different temperatures.

The studies are conducted in different stages. We start in the laboratory with heat treatment in small test tubes. The spores are then added to food and heat-treated in small bags. Thereafter the trials are scaled up to test real food products that are exposed to different amounts of heat and high pressure.

We have documented how different combinations of pressure and heat kill spores, and that it is possible to process food at lower temperatures when combined with high pressure. Our opinion is that the changes in taste, colour and texture are for the better, but the product has not yet been tested with consumers. One aim is to show that this is a technology that can be used on many types of seafood products.