Putting the squeeze on food bacteria

Using twice the pressure you would find at an ocean depth of 11,000 metres we can rid food of bacteria in a new and rather delicate way.

Denne artikkelen er over ti år gammel og kan inneholde utdatert informasjon.

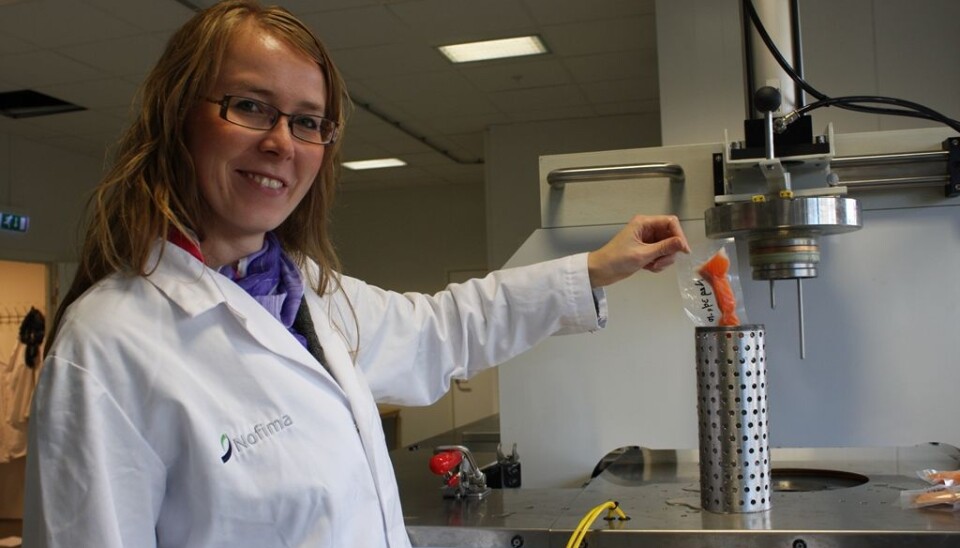

Tone Mari Rode experiments with methods for making food safer to eat through the use of high pressure.

“Because the food is subjected to equally high pressure from all sides it isn’t squashed, like a grape would be between your thumb and forefinger,” explains Rode, who is a researcher at Nofima Norway.

But why not simply stick to traditional pasteurising and heat treatment, which is how we usually get rid of potentially harmful microorganisms and increase the shelf life of most food products on the market?

An advantage with high pressure is that unlike heat it doesn’t cause any significant decrease in the nutritional value of foodstuffs.

It could provide us with more healthy foods and beverages, free of bacteria, on grocery store shelves.

High-pressure juice on the market

The machine that Rode uses is the only one of its kind in Norway. It can subject food products to 2,000 – 6,000 bars.

By comparison, the deepest spot in the oceans, the Mariana Trench at a depth of 11,000 metres, has a pressure of around 1,100 bars.

Nofima has had its high-pressure equipment up and running for about a year and it’s being used in a number of research projects. The scientists are investigating the effect of extreme pressures on food.

Private firms have also tested their products in the machine and are intrigued. It’s not unlikely that food on our future plates will have been given the big squeeze.

The Norwegian company Fellesjuice has already launched three high-pressure treated juices.

Subjecting foods to super-high pressure is a relatively new technology but is already becoming more common in some countries, such as the US.

“One of the reasons why we haven’t used the method more in Norway is that we haven’t had so many food scandals, which would be an incentive to develop and use new technology to improve food safety,” explains Rode.

Destroys the cell walls of microorganisms

Once you have the advanced high-pressure machine, the procedure is easy as pie. You put the product in a vacuum package you’ll be marketing it in and place it in the machine.

The extreme pressure ruptures the membrane of bacterial cell walls and stops most bacterial processes. Microorganisms are imploded and rendered harmless.

“The advantage of pressure-treating the end product in its commercial packaging is that you eliminate the risk of more bacteria getting in there before it reaches the consumer,” she says.

Some larger molecules and proteins are broken up by the ordeal, but vitamins and other nutrients go scot-free. The use of additives and preservatives required for normal preparations can be averted.

Guacamole, cold cuts and juice

The first product that was treated with high pressure treatment was guacamole dip – the treatment kept the crushed avocados fresh and green.

“The pressure breaks up an enzyme that causes the browning,” says the researcher.

But not all foods are suited to high-pressure treatment. In addition to guacamole, the most likely candidates are juices, smoked sausage, sandwich meats and certain ready-made foods.

Raw, whole cuts of meat are not suitable. The process can change the colour and consistency of meat. This is what Rode and her colleagues are researching – ways in which different foods are affected.

Juice turns out tasting better and the quality of other foods that are preserved more traditionally could likewise be boosted.

Not reversing processes

The high pressure machine rids food of bacteria. In apple juice it gets rid of the potentially harmful bacteria that are naturally found in apples.

“This treatment also destroys some enzymes, giving the juice a fresh-squeezed taste that lasts even after it’s been stored a long time,” says Rode.

The machine works fast. After five minutes the product is bacteria free and safe to eat. It also uses less energy than heat treatment.

But according to Rode it’s not a machine of the future you’ll have in your kitchen to turn old rotten fish into fresh and tasty fare.

“It can’t reverse processes in the food that have already occurred.”

------------------------

Read this article in Norwegian at forskning.no

Translated by: Glenn Ostling