Here’s how valuable resources can be extracted from the seabed: “There's a goldmine out there”

If there is going to be seabed mining, how should it be done? And what kind of technology can we use?

“There's a goldmine out there. Literally. Both gold and silver,” Egil Tjåland says.

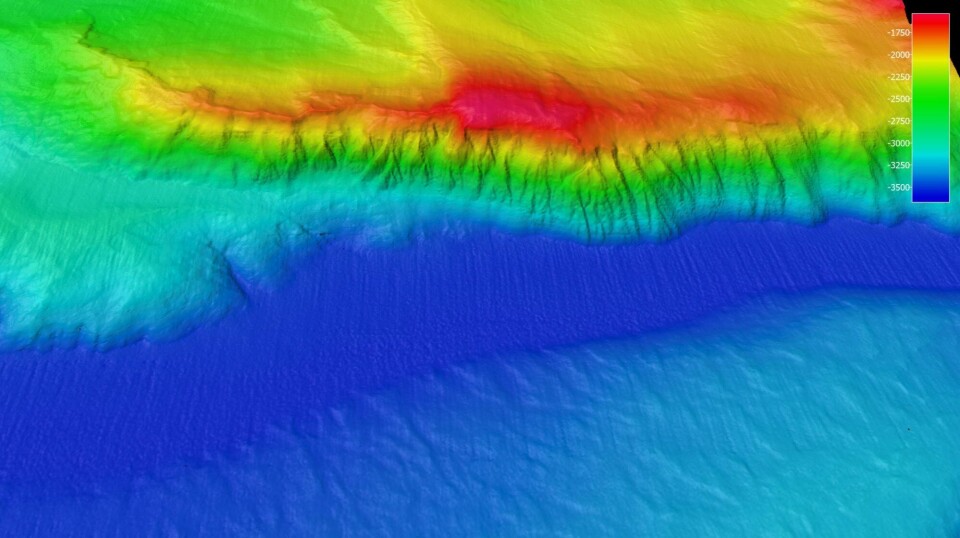

Tjåland is describing the mineral deposits in the deep sea between Jan Mayen and Svalbard, about 1,000 km northwest of mainland Norway.

Tjåland is associate professor at the Department of Geosciences and Petroleum at the Norwegian University of Science and Technology (NTNU) and general secretary of the Norwegian Forum for Marine Minerals, an interest organisation for the extraction of seabed minerals.

The depths of the Norwegian sea contain the Arctic section of the mid-Atlantic Ridge. This is a dramatic underwater mountain landscape with volcanoes that are constantly erupting.

Most viewed

No content

The Norwegian government has proposed opening up a large area of the Norwegian continental shelf for exploration and possible mineral extraction on the seabed.

Worth as much as the Norwegian Oil Fund?

The matter is now being considered by the Energy and Environment Committee and will be voted on in the Storting, the Norwegian Parliament.

The government points out that resources on the seabed can contribute to meeting a large and growing demand for metals in the future. In old undersea volcanic areas, the Norwegian Petroleum Directorate expects to find more than 38 million tonnes of copper and 45 million tonnes of zinc. It’s also likely that there are large amounts of cobalt – and several thousand tonnes of silver and gold.

Seamounts and cliffs are expected to contain several million tonnes of manganese, magnesium, cobalt, vanadium, and titanium, as well as a number of rare-earth minerals.

That’s how the deposits were described by the Norwegian Petroleum Directorate in its own resource assessment (link in Norwegian).

How much is this worth? Egil Tjåland has done a simple calculation and multiplied the tonnes in the report with prices for various metals.

“The number I came up with is as big as our Oil Fund is now,” he says.

The Norwegian Oil Fund, or more correctly, the Government Pension Fund Global, is among the world’s largest sovereign wealth funds, with roughly 1.48 trillion USD in assets.

The estimate contains a lot of uncertainties, since metals and mineral prices change all the time, Tjåland notes.

An example is cobalt, which can be important in making batteries. In 2021, the price was very high, at around 60,000 USD per tonne. This autumn, the price is down to around 32,000 USD, according to Reuters.

An industrial adventure

“I think this could be a very exciting industrial adventure for Norway,” Tjåland says.

Others think that the process is going too fast and that not enough is known about the environmental consequences, sciencenorway.no wrote in November.

No one is engaged in commercial mining in the deep sea today. How do you even retrieve metals from a depth of several thousand metres, and what kind of environmental impact is involved?

How should it be done?

There are many proposals for how the extraction itself and the work in the depths should take place, but much remains unclear.

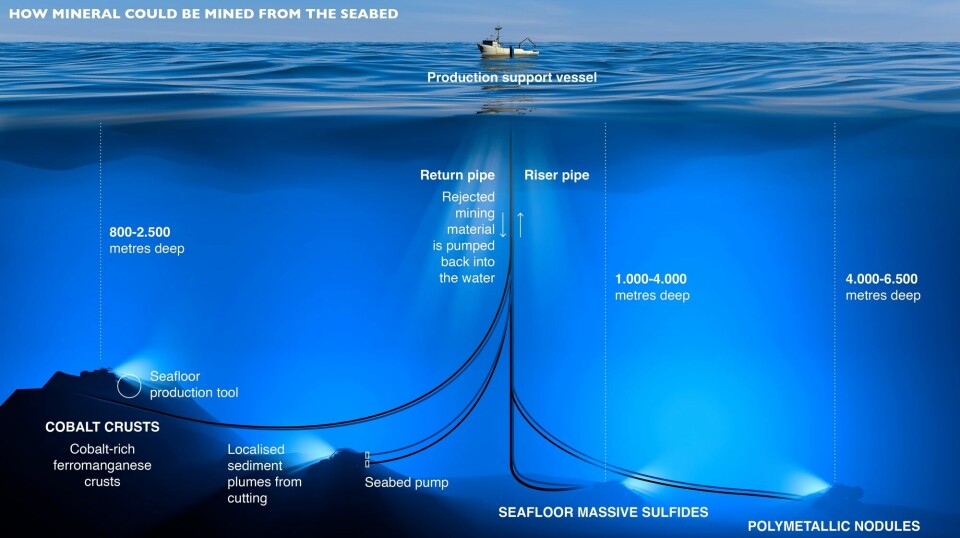

There are primarily two types of mineral deposits that are relevant in Norway. One is so-called manganese crusts – crusts that can be several tens of centimetres thick with valuable minerals that lie on bare rock crags deep in the ocean.

The other is old, inactive chimneys – places where there have been outflows of hot water loaded with minerals and metals that have built up over many thousands of years. At some point, they collapse and leave behind piles of rubble, where the metals can extend several hundred metres down into the seabed.

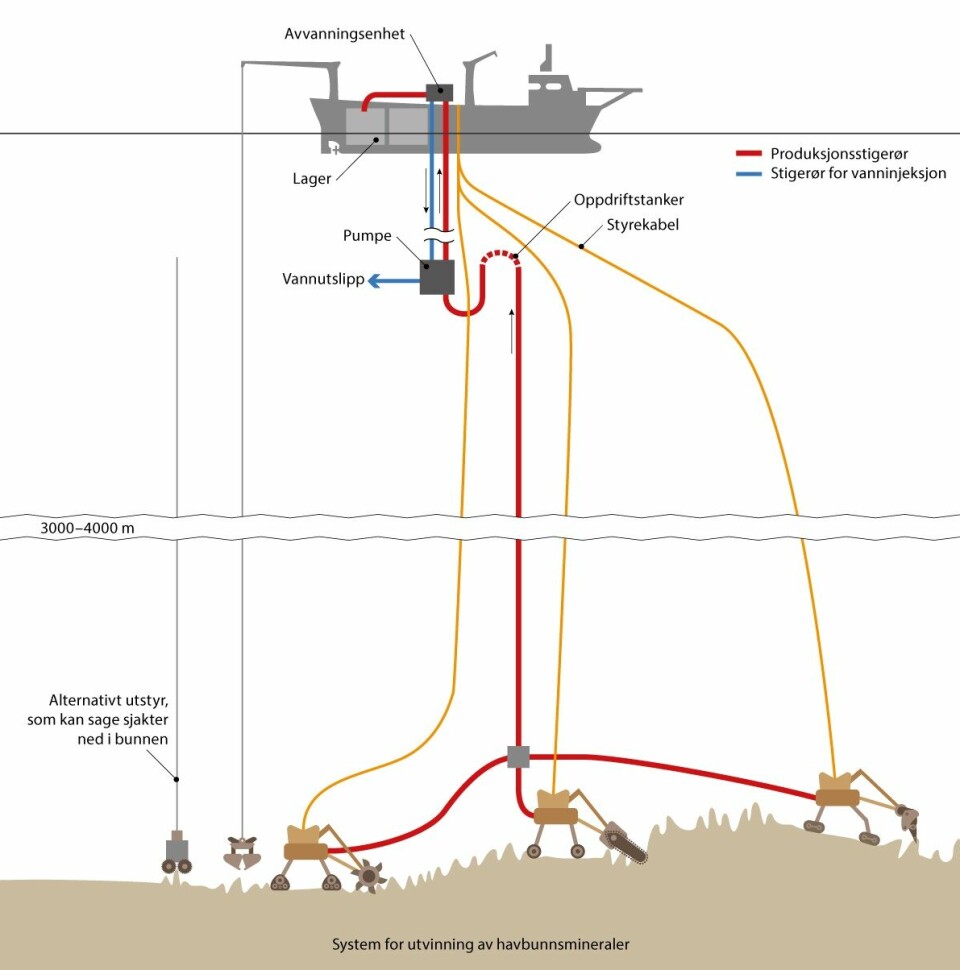

The manganese crusts need machines that can cut into steep underwater cliff faces. Tjåland says there are several possible solutions. There may be machines that plane off the crust to collect it – a sort of cheese slicer principle.

There may also be machines on tracks that can climb steep cliff faces or powerful water jets and vibrators that crush the crusts, according to a Norwegian impact assessment for seabed minerals from 2022 (link in Norwegian).

For the old chimneys – so-called sulphide deposits – there may be techniques that are more similar to traditional mining on land, just adapted to the sea. For example, platforms on the bottom that can drill shafts down into the seabed.

Hundreds of metres down

“The advantage of these deposits is that they are concentrated in small areas,” Ellefmo tells sciencenorway.no. He is a professor at the Department of Geosciences and Petroleum at NTNU and studies mineral extraction in the deep sea.

He says that the sulphide deposits are small in extent, but can be several hundred metres deep.

Because the deposits possibly contain a higher proportion of metals than similar deposits on land, more metals can be extracted per tonne of rock that must be extracted, Ellefmo says.

What most of the technologies needed for this situation have in common is that they are still in the early development phase. The Norwegian impact assessment calls them immature technologies.

There are several challenging aspects, Ellefmo points out. For example, the equipment must be launched from a ship – in all kinds of weather and under many different conditions.

Two big unanswered questions

Tjåland believes that the most important thing now is for politicians to pave the way for the exploration of seabed minerals, so that technology development can follow.

“If you give Norway a technological challenge, we will solve it here,” he says.

Tjåland believes that initially, several technologies will be tested before they possibly find something that works.

“This will lead towards a more streamlined arrangement that also takes the environmental aspects into account,” he says.

He emphasises that economy and environment are the two major decisive factors for extracting minerals from the seabed. There must actually be enough minerals and metals down there, and the technology must make it profitable to operate, according to Tjåland.

“If it's not worth it, no one will do anything about it, absolutely guaranteed,” he says.

Millions a day?

Steinar Ellefmo also points to possible environmental effects and whether it will be profitable or not. He believes that it is currently very difficult to make any definitive statements about this.

One of the problems is that it will be very expensive to maintain a ship and production equipment far out at sea, according to Ellefmo. This is different from normal mining on land, where, for example, it costs little if production has to be temporarily shut down.

But at sea, bad weather can cause everything to stop.

“It may be that you don't get one gram, but it still costs millions per day to have a ship out there with a crew,” he says. “It's also obvious that we have to understand the ecosystems better."

Unknown environmental effects

“If the environmental challenges become too difficult or too dangerous, then mining will be stopped or at least delayed until the situation is more under control,” Tjåland says.

One big unanswered question is how much sand, particles, and 'dust' will be churned up by the mining machines. It is also unknown how much they will affect life on the seabed, at active hydrothermal vents, or in areas where there is life along the seamounts.

There may also be particle emissions from ships in connection with the cleaning and extraction of minerals and metals that are transported up to the ship from the seabed.

One proposal that could address these problems, is to create closed systems that will reduce emissions of both particles and metals into the water, according to the parliamentary report on seabed minerals. Other proposals involve transporting these masses up in closed containers or releasing cleaning water right down at the seabed, so it does not spread more than necessary.

But many unanswered questions remain.

What’s happening elsewhere?

Experiments and research have been conducted for a number of years across the globe, but there is still no commercial industry mining on the seabed.

An early, large project was planned for Papua New Guinea, run by the company Nautilus Minerals. This company went bankrupt in 2019, partly due to financial problems and local opposition, according to industry website Mining.com.

China and the USA are among the countries where there is both interest in extraction and where tests have been conducted.

Japan has collected samples of manganese crusts and sulphide deposits, and began testing in 2017. The country has declared it will begin exploration and production of rare and sought-after minerals and metals in 2024 at the tiny Japanese atoll of Minamitorishima in the Pacific Ocean.

Here, the search will take place at a depth of 6,000 metres, according to the Nikkei Asia newspaper. The main reason is that Japan wants to become less dependent on China for obtaining these metals, according to the newspaper.

Ongoing for several years

Companies have been working in the Pacific Ocean on developing methods to pick up so-called metallic nodules. They are a type of mineral deposit that has not been found in Norway. The nodules consist of potato-like lumps of minerals that lie scattered on the seabed.

The Canadian company The Metals Company has had test projects for several years in the Pacific Ocean off Mexico. A video from the company itself shows an example of the technology it uses to collect the nodules. Tjåland told sciencenorway.no that this is by far the most mature technology for conducting mineral extraction on the seabed.

The Metals Company will submit an application to begin commercial mining in 2024 and believes it could be ready to produce in 2025, according to the company's website.

But this approach is not likely to be relevant on the Norwegian seabed.

———

Translated by Nancy Bazilchuk

Read the Norwegian version of this article on forskning.no

NORI & Allseas – First Integrated Collection System Trials Since 1970s from The Metals Company on Vimeo.