Norwegian invention can decrease CO2 emissions

A new Norwegian technology can remove nearly 90 percent of the carbon dioxide emitted by coal-fired power plants.

Denne artikkelen er over ti år gammel og kan inneholde utdatert informasjon.

Scientists at the Norwegian University of Science and Technology (NTNU) in Trondheim have developed a promising new method for removing the greenhouse gas CO2 from industrial emissions using a thin membrane that coats hollow fibres.

“The main advantage is that the process is eco-friendly. We use no chemicals,” says Professor May-Britt Hägg at NTNU.

The method could be useful in removing CO2 from the smokestacks of coal-fired power plants and other industries that produce lots of the greenhouse gas.

Copies our lungs

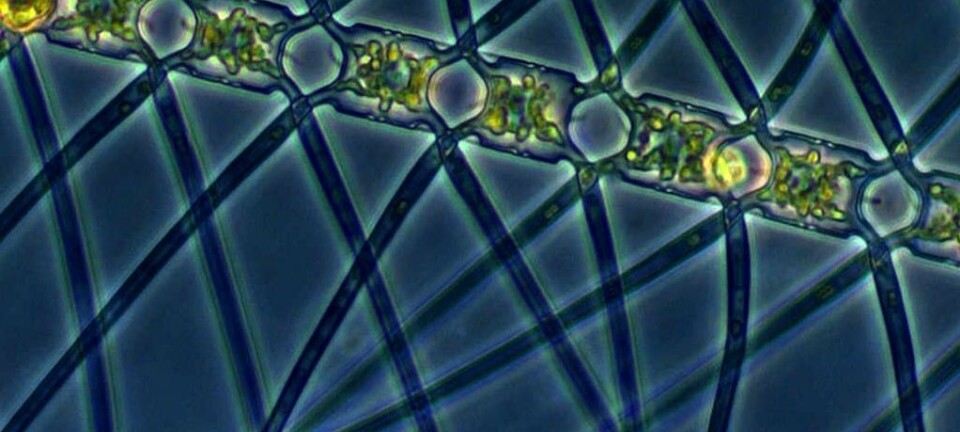

May-Britt Hägg and her colleagues have spent years developing a plastic membrane, a thin sheet of nano-structured polyvinylamine, which lets CO2 pass through but no other gasses. A gas-fired power plant at Mongstad in Norway is currently building a liquid amine plant to capture carbon dioxide. But Hägg puts the amine (an organic nitrogen compound) into the membrane.

The membrane is just one micrometre thick, which is much thinner than the plastic foil you use in your kitchen.

This makes it necessary to mount the membrane on a stronger material that functions as a structural support.

“The process occurring in the membrane is comparable to what transpires in our lungs when we breathe,” says Hägg.

An enzyme in our lungs helps CO2 to pass extremely rapidly through the walls of lung tissue. Instead of an enzyme, Hägg and her colleagues use different pH values (degree of acidity) to control the efficiency of CO2 transport.

Hägg says the membrane can separate nearly 90 percent of the carbon dioxide from other smokestack gases.

Once the carbon dioxide gas is removed from the other gases it can be stored, for instance under the seabed, and kept from escaping into the atmosphere.

First in the world

The NTNU researchers were the first in the world to patent this type of membrane. They are at the vanguard of CO2 removal from waste gas using the membranes, although other scientists elsewhere in the world are working along the same lines.

Hägg and colleagues have experimented with several prototypes of support structures for the membrane, including flat sheets. Tests of the membrane on such sheets have been successfully conducted at a coal-fired power plant in Portugal.

The shape they are now pursuing consists of hollow fibres that will have an outer wrapping composed of the membrane.

This kind of shape can be packed tightly together to create a huge amount of surface area in a limited volume, so the module takes up minimal space.

Fossil fuels for some time to come

May-Britt Hägg got interested in membranes in the late 1980s during a lecture. It has taken until now for the technology to start bearing fruit.

“I’ve always been concerned about the environment − but I’m a realist. We aren’t on the verge of breaking away from fossil fuels,” she says.

“If I were young I might oppose all use of fossil fuels, but now I know so much about the world’s energy situation that I prefer to be in the game and try to do something pertaining to our actual use of such fuels.”

Hägg has experienced a lot of interest in the technology. A membrane manufacturer from abroad and a team of Norwegian and international energy and oil companies are involved in further developments.

“I’m along in my years but I hope to see the technology in use before I retire,” says Hägg.

------------------------------

Read the Norwegian version of this article at forskning.no

Translated by: Glenn Ostling