40-tonne steel rigs will protect the Viking ships during the building of a new Viking Age museum in Oslo

The Viking ships have remained in the same place since they were first put on display. Now they are being moved, with comprehensive security measures in place to ensure they are not damaged.

Construction of the new Museum of the Viking Age in Oslo starts during the first week of February. The doors of the new museum are set to open in 2026. This means that the exhibition in the current Viking Ship Museum is unrecognisable.

“All of the almost 400 objects in the exhibition, save for six, have already been moved to the museum’s storage facilities in Økern,” conservator David Hauer from the Viking Ship Museum says to the Norwegian News Agency, NTB.

He is responsible for ensuring that none of the museum’s objects are damaged during the entirety of construction and moving.

Placed in steel rigs

Some of the museum’s more than a thousand-year-old objects are, however, too large to be stored anywhere else but where they currently rest – and they would in any case be too fragile to be moved any distance.

The Oseberg ship, the Tune ship and the Gokstad ship will in fact largely be left where they are during the construction process. Hauer has spent years trying to figure out how to conserve these ships while also preventing damage while the machines are drilling away outside the museum walls.

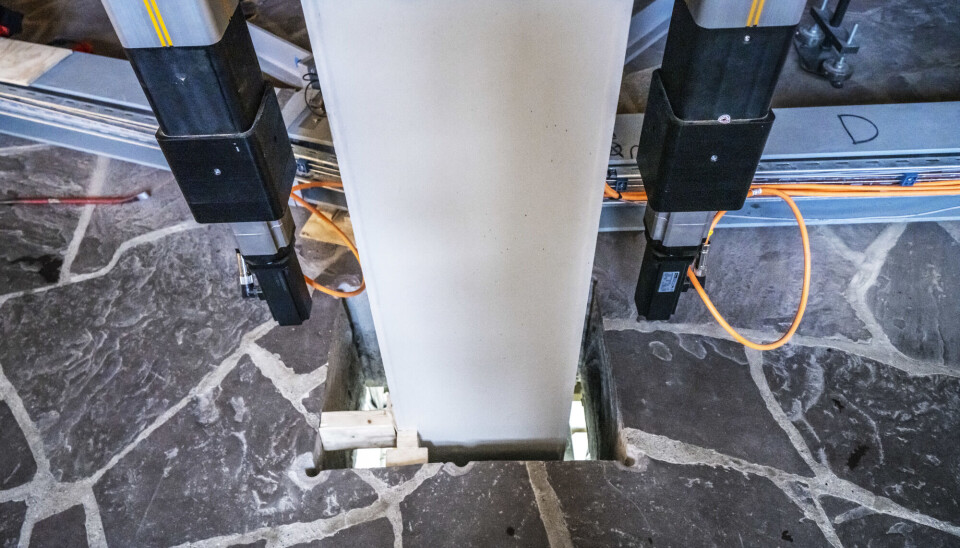

The solution has been to give the ships a new outer layer. The Tune ship has already been encased in the steel rig made to secure it from vibrations in the floor, caused by the construction about to start outside. It weighs 40 tonnes and is produced by the Stavanger-company Imenco Smart Solutions – a company that usually produces equipment for the oil rigs in the North Sea.

“We’re now working on lifting the ships into these rigs to isolate them from the vibrations. Inside the rigs they will be resting on air suspension, in the exact same spot for around two years until the framework of the museum is ready,” Hauer says.

Transported on tracks

The rigs are so heavy that the museum floors cannot hold them. This has been solved by drilling through the floor so they can rest on the foundation the museum was built on.

To transport the ships to their new exhibition spots in the new museum, tracks are being laid inside the building.

The Viking ships will be transported about 200 metres before they are lowered into an elevator and then placed in their particular spots.

The most fragile objects in the museum are three sleighs that belong to the Oseberg find.

“These have been moved internally in the Viking ship museum with a rig that weighed three tonnes and moved on tracks, to a specially constructed secure room,” Hauer says.

Many considerations

Never before has anyone tried to secure and move Viking ships and fragile archaeological artefacts in this way. This means that there has been no previous experience to learn from.

“In normal construction processes everything has to be according to protocol, but in this project we have had to develop everything ourselves,” Hauer says.

The six-year long project will be put to the test early February, and Hauer believes they have developed good solutions.

The construction workers have to be very considerate during the building process.

“We will monitor everything that goes on during construction. We have set limits for climate, deformation, and vibrations. If anything surpasses these limits we get a warning so we can stop the construction process,” Hauer says.

Translated by: Ida Irene Bergstrøm