New material for solar cells

The raw materials are abundant, cheap and environmentally friendly. Metal hydrides can represent the next breakthrough for solar power.

Denne artikkelen er over ti år gammel og kan inneholde utdatert informasjon.

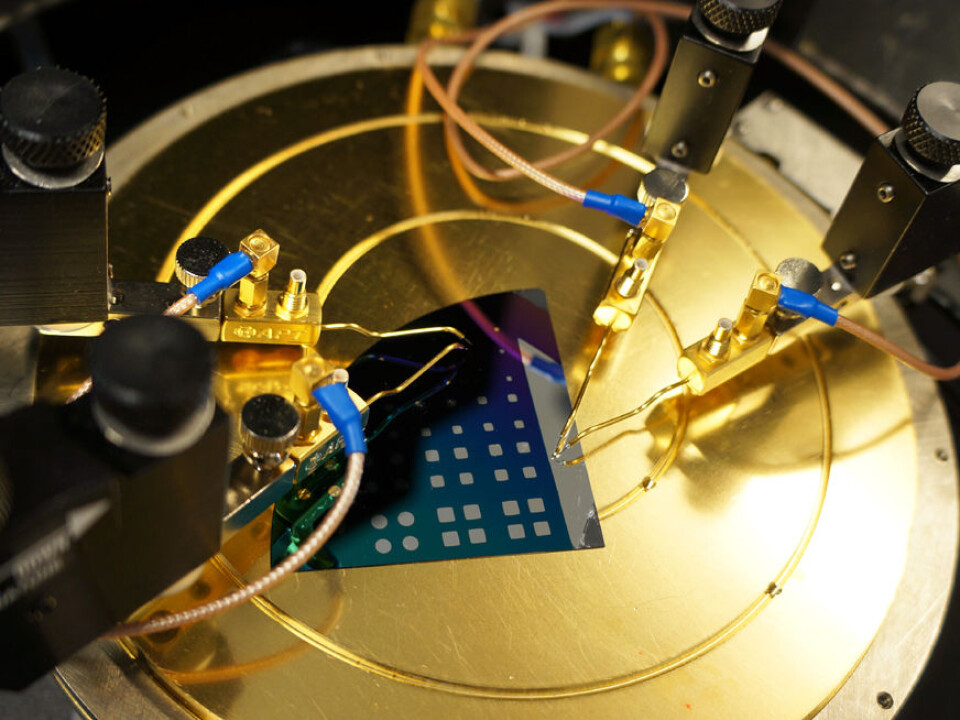

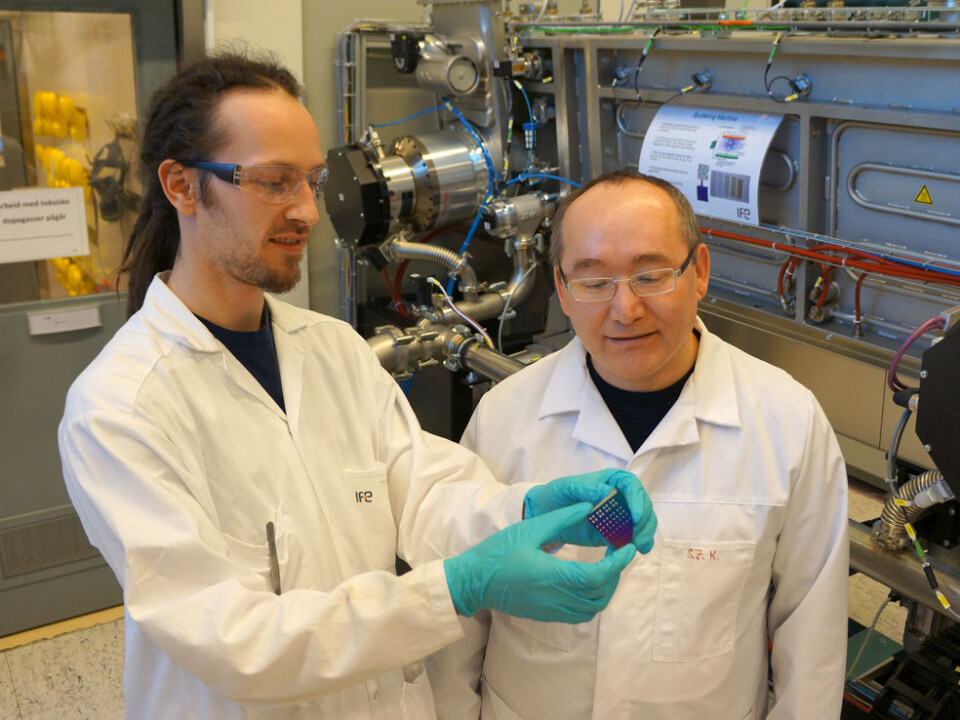

Research Fellow Trygve Mongstad lifts a little disc into the sunlight. The glass plate has a thin coating of vaporised magnesium-nickel hydride.

“These metallic hydrides are chemical compounds consisting of a metal bound with hydrogen,” he explains.

At the Institute for Energy Technology (IFE) at Kjeller, Norway, they do research on new powders of metal hydrides where one of the uses is in hydrogen fuel-cell cars.

When metal hydrides are heated the hydrogen can be released and used in fuel cells. But Mongstad isn’t working with hydrogen storage.

“Here at IFE’s solar energy department we are experimenting with exciting new uses for the characteristics of metal hydrides,” he says.

Mongstad hopes – but cannot say for sure – that metal hydrides can be put to the same use in solar cells as silicon.

Getting cheaper

So what’s wrong with silicon? Isn’t it environmentally friendly, clean and cheap? Didn’t the Norwegian solar cell firm REC recently have to lay off scores of employees because world market prices have plummeted?

“Solar cells are cheaper than ever but still not affordable enough for solar energy to compete on a large-scale with, for instance, coal-fired power plants,” says the researcher.

REC and the rest of the solar cell industry are experiencing hard times. But according to Mongstad these will pass. He thinks that in the long run demand will explode and new technologies will be entering the market.

Mounting efficiency

From this perspective metal hydrides can be very promising. If Mongstad and his colleagues achieve their dreams, in five or ten years they can deliver cheap solar cells with an efficiency of over 20 percent.

Efficiency in this context means how much of the solar energy is converted into electricity. Solar cells in today’s market have an efficiency of 10 to 20 percent, depending on the technology used.

“An efficiency of up to 43 percent has been demonstrated. But these are extremely costly solar cells manufactured from very expensive materials,” he explains.

More layers, more colours

The use of multiple layers is exactly what could be the promising way to press those last watts out of solar cells.

“It’s not a case of metal hydrides or silicon. We envisage the use of both of them in layers,” says Mongstad.

By laying a thin layer of vaporized metal hydrides onto the thicker silicon cells, more of the colours in sunlight can be used and higher efficiency is achieved.

On the top layer researchers can add a metal hydride solar cell that absorbs light from the blue end of the sunlight spectrum.

The sunlight also shines into a normal silicon solar cell, which is most effective in utilising the energy of red light at the opposite end of the spectrum.

Various metal hydrides can be combined in this way, each of them particularly sensitive to different colour ranges. The use of different metals can be fine-tuned for maximum efficiency.

Cheap and available

Metal hydrides also have their intrinsic advantages. The raw materials are readily available and consist of cheap metals and hydrogen. These materials are environmentally friendly and in this context non-toxic.

As the thickness is just one-hundredth of that of silicon cells, they require less energy to manufacture.

If Mongstad and his colleagues manage to create solar cells from metal hydrides, they can help get solar energy out of the doldrums.

The race to the bottom line

“All the solar cell producers in the world are trying to get the price of solar power down,” he says.

Non-subsidised solar power is only cheap enough to be competitive a few places in the world, notably in California, Hawaii, parts of Australia, Spain and Italy.

But other countries are on their way. In Germany new solar power installations that can produce a total of 3 gigawatts were installed as recently as December last year.

“During the sunniest hour the country had in 2011, nearly a third of Germany’s power consumption came from solar energy,” says Mongstad.

Local solar energy

The world’s second most populous country, India, is also on the threshold of the solar age. And if consumers in Africa had the funds for investing in small local solar power plants, they would start making a return on their investments after only two years, when compared to the diesel generators ubiquitously used today.

Most of the future solar power development will be in local installations, believes Mongstad. As solar cell prices drop and efficiency mounts, the transmission of power from one place to another will represent a relatively higher share of total costs.

“The sun shines all over the place! I think we will be seeing some thrilling developments in solar power in the next decades. Maybe solar cells based on metal hydrides will help fuel this development,” says Mongstad.

-------------------

Read this article in Norwegian at forskning.no

Translated by: Glenn Ostling