An article from Norwegian SciTech News at SINTEF

Aviation fuel from Norwegian forests

Scientists believe it will be possible to manufacture a competitive aviation fuel from wood by 2020-2025.

Denne artikkelen er over ti år gammel og kan inneholde utdatert informasjon.

A recent report concludes that two technologies appear promising based on Norwegian conditions.

In one of the processes, timber is gasified and biofuel is produced using a Fischer-Tropsch plant. In the other, alcohol produced from wood pulp is refined to produce aviation fuel (the alcohol-to-jet-process).

On behalf of the Rambøll consulting company, SINTEF Energy Research has carried out a study of the most relevant technologies for creating biofuel for Norwegian aircraft.

Several contributors to final report

Two years ago, Avinor, the state-owned company responsible for planning, developing and operating the Norwegian airport network, took the initiative for a detailed study of the possibilities for producing aviation fuel. The company invited public tenders and Rambøll’s was accepted. Since then, Rambøll has divided the job up into five work packages.

The study of appropriate technologies is one of several investigations included in the total package which has now been presented. Other themes are forestry-based resources, biomass import, logistics/infrastructure and seaweed/algae.

The technologies assessed

“In the gasification process, we heat timber to high temperatures. The gas released in this process is converted to liquid biofuel by means of the complex Fischer-Tropsch process. This creates hydrocarbon chains of various lengths,” Berta Matas Guell of SINTEF Energy Research explains.

“To produce aviation biofuel the chains must consist of a certain number of carbon atoms. Since some of the hydrocarbon chains produced contain too many carbon atoms, the longest must be shortened in a so-called “hydrocracking” process.

The other method SINTEF believes will be suitable based on Norwegian conditions consists of converting alcohol produced from wood pulp into aviation fuel. The part of the process in which alcohol is converted into fuel is already in large-scale use in the petrochemical industry. The technical challenges lie principally in the production of the alcohol.

“Research scientists have also considered producing aviation fuel using oilseed as a raw material, but the drawback is that Norway does not produce large amounts of oilseed and the production of such seed would be in competition with other food production, which would affect the sustainability,” Matas Guell points out.

Certification

A factor which must be taken into account is that the aviation industry has strict requirements for the certification of aviation fuels. At present two of these three fuels have been certified – the Fischer-Tropsch process and the oilseed process.

But even if the processes are certified, the fuels must still be mixed with 50 per cent conventional, fossil-based fuel.

“Alcohol-to-jet is not certified as an aviation fuel,” says Berta Matas Guell, “but the certification process has now commenced.” According to her, a positive aspect is that this certification probably will not stipulate combination with conventional aviation fuel.

Many factors to take into account

Rambøll, which specialises in sustainability, thus concludes that it will be technically and economically feasible to produce aviation fuel from the forests of Norway by 2020-25. The company considers the Fischer-Tropsch technology and alcohol-to-jet to be the most appropriate technologies. This is in agreement with the conclusions of SINTEF Energy Research.

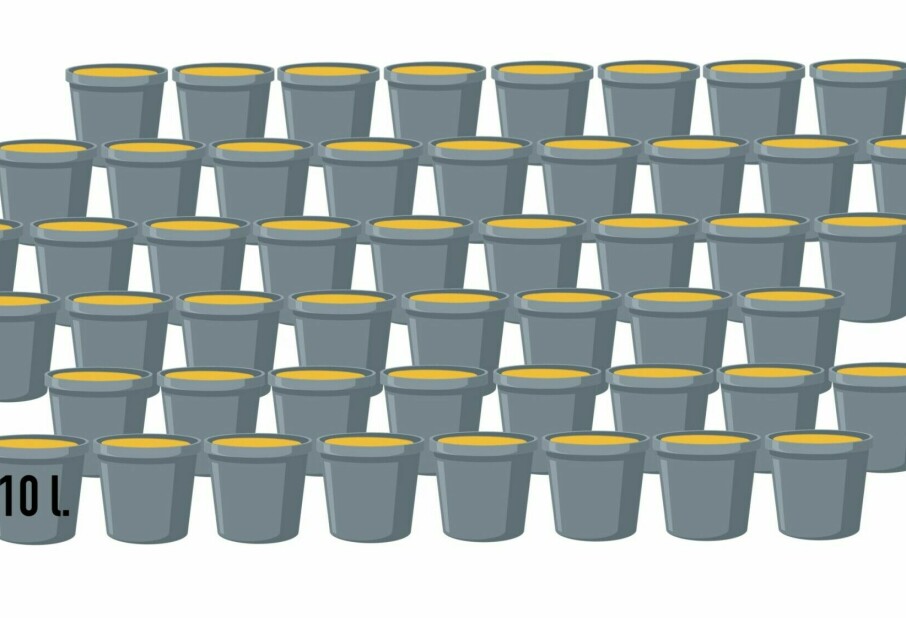

Rambøll tells the Norwegian technology magazine Teknisk Ukeblad that the price per litre of Jet A-1 produced by the Fischer-Tropsch process will be competitive with fossil-based Jet A-1 by 2025, but this conclusion is based on the construction of several such plants by that time, and on the ability to sell the by-products of the production process, such as biodiesel and bionaphtha.